Passive sampling and its pivotal role in greener sampling of VOCs

16 December 2020

Passive sampling is the simplest way to collect air samples for analysis. It is used to assess the levels of pollutants and chemicals in the air, including particulate matter, inorganic pollutants and volatile organic compounds (VOCs). A passive sampler is a collecting medium that can be a solid or liquid sorbent or a chemically impregnated inert support. When samplers are introduced to the atmosphere of interest, they sample by diffusion.

Passive sampling began in the 1920s to evaluate pollution levels in trees. It was further refined in the 1970s when concerns about VOCs in air prompted the beginning of passive air monitoring with charcoal. The method involved pumped sampling onto single-use glass tubes packed with charcoal followed by carbon disulfide extraction and GC analysis.

In the late 1970s and early 1980s, thermal desorption (TD) was adopted instead of the solvent extraction technique for monitoring VOCs whereby sorbent tubes containing air samples are heated in a flow of inert gas to release the trapped compounds. This resulted in a significantly more sensitive technique compared to solvent extraction because there is no masking of peaks by solvent peaks on the resulting chromatograms. Sorbent tubes require no solvent to extract compounds and can be reused multiple times, making them a ‘greener’ option. Also, analysts are no longer exposed to hazardous solvents and laboratory solvent waste is eliminated.

Sampler types

There is a choice of geometries with passive sampling devices, depending on the type of sample you want to collect, what concentrations you want to get down to and how long you want the sampler to be exposed for.

Samplers to collect VOCs in air are grouped into two categories (Figure 1):

- Axial samplers – one surface of sorbent is exposed to the air, giving it a slower analyte uptake rate, making it ideal for sampling over long periods.

- Radial samplers – a significantly greater surface area of the sorbent is exposed to the air, giving it a higher analyte uptake rate, making it ideal for shorter sampling periods.

Figure 1: An axial sampler (left) and a radial sampler (right).

Which sampler type should you use?

Axial and radial samplers suit different sampling situations. With axial samplers, the tube is held vertically with the sampling end exposed. Vapours migrate across the air gap at a constant uptake rate. It’s a slow process so is most suited to applications that need long sampling times (4–8 hours for workplace monitoring and 1–4 weeks for environmental air monitoring, for example).

Radial samplers can be used horizontally or vertically. They work under the same principles as axial sampling, but the whole sorbent area is exposed to the air. The sorbent is enclosed by a porous body, which acts in the same way as the sampling end. As uptake rates are faster due to the large surface area of sorbent exposed, the samplers can collect more mass of a compound of interest over a shorter period, and achieve the same detection limits as an axial sampler within this time. Radial sampling is suited to shorter monitoring periods (such as 1–8 hours for workplace monitoring and up to 1 week for environmental air monitoring).

Choosing the correct geometry for your application depends on the sampling duration required, the concentrations of the (known or expected) target compounds. For example, if you are looking for low concentrations in a short period, a radial sampler would be the best option. If you’re looking for low concentrations over a longer period of time, an axial sampler would be best. Choice of sampler also depends on the compounds of interest and the environment being sampled.

Where can passive sampling be used?

Passive samplers are commonly used for:

- Occupational health monitoring

- Industrial perimeter monitoring

- Pollution mapping in urban areas

- In-situ soil contaminant mapping (looking for contaminated areas when doing land remediation)

- Vapour intrusion investigations

- Indoor air quality assessments

For further information on which sampler to choose, please see standard methods ISO 16017:2, EN 838, EN 14412, EN13528 and MDHS 80.

Below are real-world examples of how passive sampling has been used.

Pollution mapping in urban areas

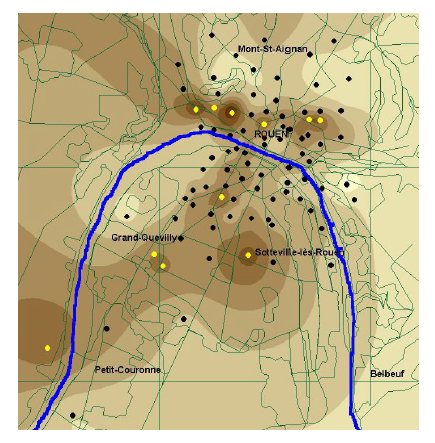

In one large-scale urban air monitoring study, 90 passive axial TD tubes were deployed in a city in northern France over a two-week period to assess concentrations of the carcinogen benzene. The results are shown on the map in Figure 2. The highest benzene concentrations (shown by the yellow dots) occur where there’s an airport and industrial areas in the south, both of which are possible sources of the benzene. The area to the north marked with yellow dots is interesting because there isn’t an industrial area. Here, there are large cliffs to the west, a canyon to the north and ridges to the north-east. It has been assumed that these topographical features are causing pollution from the industrial area in the south to build up as there is only a narrow outlet.

Figure 2: Passive sampling was used to map benzene concentrations in a city in northern France. The yellow dots show the highest benzene concentrations.

Industrial perimeter monitoring

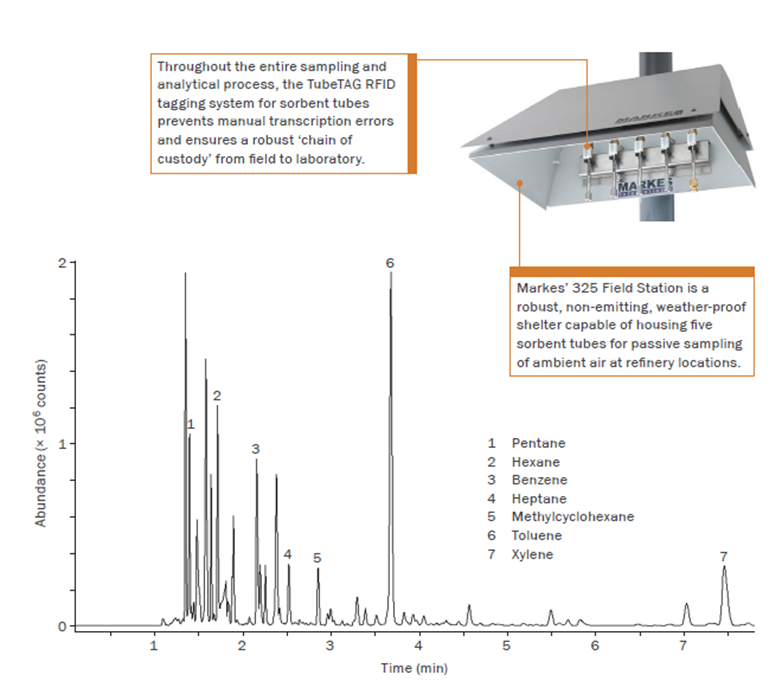

US EPA Method 325 requires that petrochemical refineries must monitor their perimeters for benzene every two weeks by passive sampling. Benzene is the primary target, but the results from one refinery (Figure 3) demonstrate that the method can be used to monitor other hazardous compounds too. This is valuable because if a few different refineries operate in one area, the concentrations of the other compounds could reveal who is to blame for elevated benzene concentrations.

Method 325 also defines how many sampling points each refinery must have around the fenceline based on the geographical area. 750-acre sites must have at least 12 sampling locations based at 20-degree intervals from the geographical centre. 750–1500-acre sites have to have at least 18 sampling locations. Anything greater than 1500 acres must have at least 24 sampling locations. If there is a benzene source within 50 metres of the fenceline, additional sampling locations are needed.

Automated thermal desorbers, such as the TD100-xr™ and UNITY–ULTRA-xr Pro, help address the challenge of Method 325 by enabling 100–199 samples to be analysed in sequence, reducing running costs and allowing unattended operation over entire weekends. Stringent leak testing, automatic addition of internal standards and quantitative re-collection (for repeat analysis) further enhance analytical rigour.

Figure 3: Axial sorbent-tube samplers were used to monitor benzene concentrations at a refinery perimeter. The other compounds on the resulting chromatogram could be used to identify the source of elevated benzene concentrations if there are several refineries in the area.

Why use passive sampling?

To conclude, there are a number of benefits to using passive sampling:

- It’s practical. There are no complex mechanical parts, and you don’t need to calibrate any pumps. You can simply place the tube out in the field, remove the cap and place the diffusion cap on. You don’t need to calibrate the sampler before monitoring and they’re lightweight and unobtrusive, which makes them ideal for personal monitoring.

- It’s economical. No pumps, electricity or gas supply is required. They’re easy to ship to and from the laboratory.

- It’s scalable. Studies can easily range from tens to hundreds of samplers with very little outlay. You can work on different sampling time periods. Passive samplers can be used from minutes up to several months, depending on the requirements.

- Finally, it’s easy to use.