Dual-TD

Double sample throughput by simultaneously processing two batches of TD tubes

Dual-TD™ is a thermal desorption system for maximising sample throughput from a dual-channel GC, by simultaneously processing two batches of sample tubes.

Featuring two TD100-xr units running simultaneously, Dual-TD instantly doubles sample throughput. It also uses ‘overlap mode’ to desorb a pair of samples while the analysis of the previous pair is still running, eliminating GC ‘idle time’. Dual-TD is compatible with any dual-channel GC, and is independently certified for operation with helium, nitrogen or hydrogen carrier gas (Multi-Gas capability).

Dual-TD is ideal for high-throughput laboratories needing to:

- Efficiently carry out large-scale sorbent tube background testing.

- Undertake targeted trace VOCs and SVOCs analysis.

- Measure total VOC analysis at scale.

Ultimate convenience

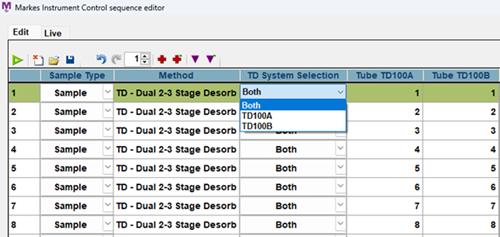

Dual-TD is designed with the analyst in mind. Markes’ easy-to-use MIC™ software is optimised for Dual-TD so only one TD sequence needs to be set up. This saves time whilst ensuring sequences remain synchronised with utmost efficiency.

Market-leading advantages of Dual-TD

Using all the innovative features of Markes' TD100-xr, Dual-TD significantly improves TD–GC productivity. The main benefits are:

- More samples in less time – ‘Overlap mode’ significantly reduces the time from one injection to the next, while run times can be further reduced by up to 40% if hydrogen is used as the carrier gas.

- Eliminate helium dependency – The Multi-Gas capability on Dual-TD allows you to use helium, nitrogen or hydrogen as a carrier gas for automated sorbent tube analysis. Using hydrogen significantly reduces run times without compromising analyte sensitivity or peak resolution.

- Sample security – With quantitative sample re-collection for repeat analysis, Dual-TD offers simple method/data validation, overcoming the ‘one-shot’ limitation of inferior TD systems. Tubes remain capped at all times, avoiding sample contamination and/or analyte loss.

- Cost saving – The electrically-cooled focusing traps eliminate the expense and hassle of liquid cryogen, and also maximise uptime by preventing the risk of ice blockages. Using hydrogen as the carrier gas will also eliminate dependency on expensive helium.

- Wide analyte and concentration range – Dual-TD can be used for analysis of VOCs from C3 to C44, including reactive and thermally labile species. The unbeatable split versatility (true-splitless to 125,000:1) also enables both high-concentration and trace-level samples to be analysed.

- Precision – Automated addition of an internal standard to the focusing trap or to a tube during analysis enhances the quality of your data.

- High data quality – Automatic leak tests carried out before analysis of each sample ensure confidence in your data quality and full compliance with key regulated methods.

- Reliability – Dry-purge or pre-purge automatically remove water and air from the sample before analysis, avoiding the risk of GC interference, and extending column and detector lifetimes.

- Simplified chain of custody – The on-board TubeTAG read/write functionality automatically updates tube and sample information during analysis.

- Method-compliance – Stringent leak testing, re-collection and a range of advanced water management options ensure full compliance with key standard methods from numerous regulatory bodies, including US EPA, Chinese EPA, CEN, ISO, ASTM, HSE, JSA and NIOSH.

- GC versatility – Compatibility with GC and GC–MS from all major manufacturers minimises the upfront investment required to investigate new TD markets for your lab.

- Easy and intelligent operation – Built-in standard-method parameters, automated self-checking diagnostics and usage/maintenance counters maximise instrument uptime.

Increased productivity with overlap mode

This graphic shows how using overlap mode with Dual-TD increases productivity by allowing more samples to be analysed simultaneously.

Download product brochure and technical specification

Dual-TD

Key applications

![Markes TD Brochure Hero3 Corepurple[2]](/media/zmscvqds/markes-td-brochure-hero3-corepurple-2.jpg?cc=0.55128205128205132,0,0,0&width=350&height=260&v=1d660d04edbcca0)