Hydrogen fuel offers great potential for clean, carbon-neutral transportation and is a top contender for replacing petrochemical fuel sources, which are significant contributors to pollution. Hydrogen can be produced from a variety of domestic resources, such as natural gas, nuclear power, biomass and renewable power like solar and wind. These qualities make it an attractive fuel option for transportation including vehicles, boats and aircraft, and electricity generation applications such as power sources in remote locations including weather stations, spacecraft and within the military.

There is, however, a challenge in adopting hydrogen for these applications – potential impurities in the supply, which can damage fuel cells, shorten component lifespans and increase pollution, negating the very reason for its use in the first place.

What are hydrogen impurities?

Contaminants that affect fuel cells include a broad range of chemicals including water, oxygen, helium, argon, nitrogen, ammonia, CO and CO2.

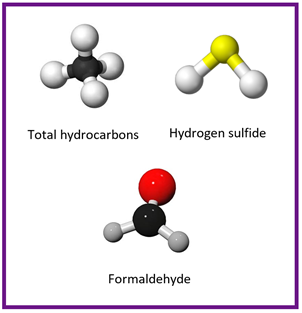

Those that can be analysed using TD–GC–MS are:

- Hydrocarbons

- Halogenated compounds

- Hydrogen sulfide and other sulfur species

- Formaldehyde

Analysis of volatile hydrogen impurities

Hydrogen quality is critical for increasing the reliability, stability and durability of hydrogen fuel cells. Any impurities present in hydrogen fuel gas may result in substantial degradation of fuel cells. The impurities can cause damage even at very low concentration levels (parts per billion). To reach these levels of sensitivity for analysis, preconcentration of the impurities is needed prior to injection to the GC-MS. While some methods call for the sum of the compounds to be reported, this technique also ensures identification of individual compounds.

Using thermal desorption coupled to a GC–MS system for the analysis of hydrogen impurities

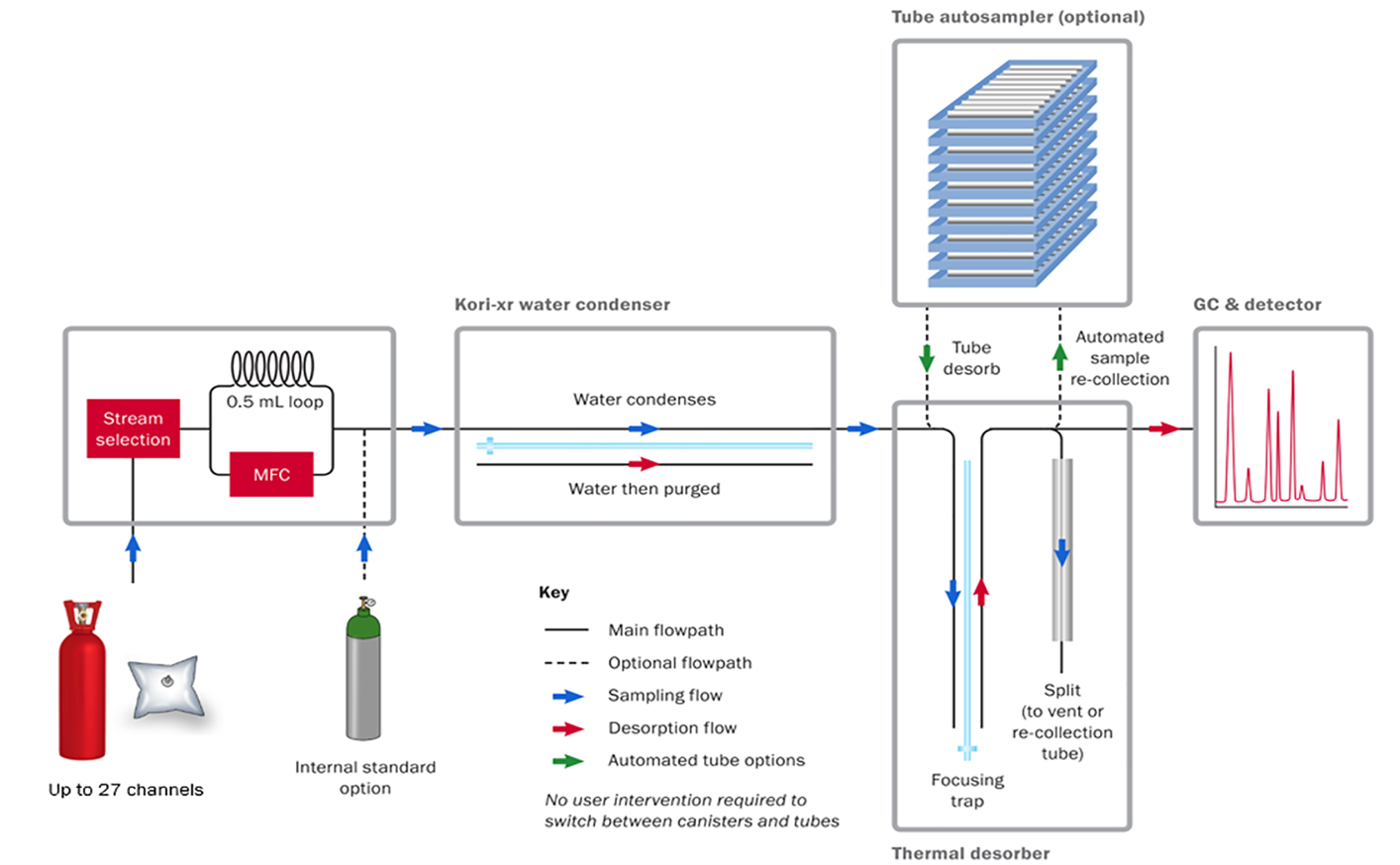

Markes offers automated sampling from on-line gas streams, cylinders and bags (UNITY–Air Server-xr™ and UNITY–CIA Advantage-xr™). An additional water management module (Kori-xr) can also be added for the analysis of humid samples – it works by removing water prior to the analysis of ultra-volatiles (e.g. formaldehyde), sulfur compounds, hydrocarbons, halogenated species, and other impurities in hydrogen fuel gas.

Sorbent tube-based thermal desorption units (e.g. UNITY-xr, UNITY–ULTRA-xr, TD100-xr) can also be used for off-line sampling. However, these tube-based approaches are not compatible with formaldehyde and hydrogen sulfide.

Both approaches are coupled with gas chromatography (GC) and a choice of various detectors: mass spectrometry for the identification of a broad range of analytes, including non-targeted compounds, or compound specific detectors, such as SCD or FID, for targeted, routine analysis.

Schematic for the configuration of the thermal desorption equipment coupled to a GC–MS system for the analysis of hydrogen impurities

Samples can be taken using active sorbent tubes for an off-line, lower cost, easy to transport sampling strategy. However, some of the very volatile compounds, such as formaldehyde and hydrogen sulfide, are not quantitatively retained when using sorbent tubes and need to be analysed using on-line TD–GC–MS or off-line via sampling bags and canisters.

Using hydrogen as a carrier gas for TD–GC–MS

The Multi-Gas -xr series of thermal desorbers from Markes has been certified for safe operation with hydrogen as a carrier gas as well as helium and nitrogen. Using hydrogen as a carrier gas increases sample throughput, protects against helium shortages, reduces laboratory running costs and enables sampling and analysis of impurities and contaminants in hydrogen fuel.

![Markes TD Brochure Hero3 Corepurple[2]](/media/zmscvqds/markes-td-brochure-hero3-corepurple-2.jpg?cc=0.55128205128205132,0,0,0&width=350&height=260&v=1d660d04edbcca0)