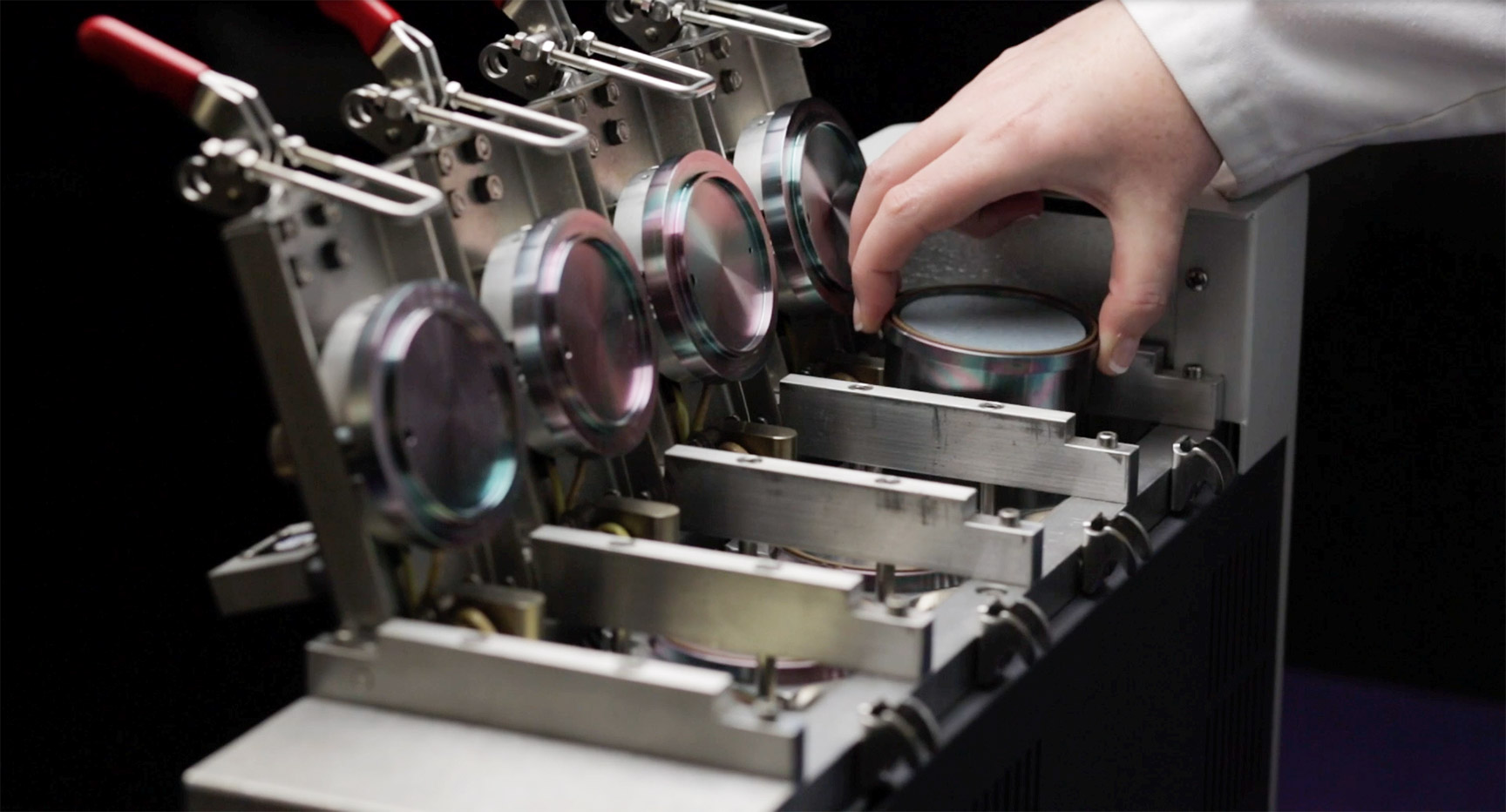

Instrument

Micro-Chamber/Thermal Extractor

Fast and flexible sampling of chemical and odours released from materials and food

Micro-Chamber/Thermal Extractor™ (µ-CTE™) is a practical tool for rapid emission screening in R&D or as part of routine factory production control. It can be used to check surface or bulk emission profiles and to assess raw materials and compare products across a range. Applications include construction materials, car trim, consumer products and profiling volatiles released from foods and fragranced products.

Analysis in booths can take anything from 15 minutes to an hour but the decontamination time is long – up to two hours. With the microchamber, I can complete the analysis in about half an hour. Then it takes half an hour to ensure the system is clean

Benefits of the Micro-Chamber/Thermal Extractor

- Fast and efficient – The µ-CTE avoids the need for time-consuming sample preparation, and sampling is complete within minutes rather than days.

- Cost-effective – Using the µ-CTE saves time and money by minimising the need for third-party reference tests.

- Wide analyte range – Released volatiles are captured onto sorbent tubes (for VOCs and SVOCs) or DNPH cartridges (for formaldehyde), and all surfaces are inert-coated for compatibility with reactive or thermally labile chemicals.

- Predict the results of reference tests – Data from the µ-CTE has been shown to correlate with longer-term tests carried out using small chambers.

- Method-compliant – The µ-CTE complies with international standard methods ISO 12219-3 (interior air of road vehicles) and ASTM D7706 (rapid screening of VOC emissions from products).

- Sampling versatility – As well as sampling emissions from bulk samples, a range of accessories allows sampling of surfaces or permeation through materials, humidification of air/gas, chamber calibration, and easy cutting of foam samples.

Download product brochure and technical specification

Micro-Chamber/Thermal Extractor

The Micro-Chamber/Thermal Extractor displays great reproducibility across all chambers