Filters for instruments

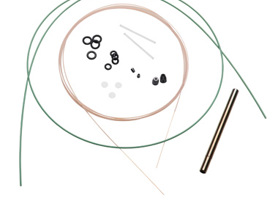

Filter disks are used in tube receivers to prevent flow path blockages. Instrument filters should be checked and replaced regularly as part of a routine maintenance plan. Split tubes can be used multiple times, but should be routinely replaced – Markes recommends at least every 12 months. Split filter tubes should never be desorbed.

- User-replaceable

- Common parts for all instrument series

- Refer to instrument manual for guidance, or talk to our technical team

Product List

Showing 6/6 results

Filter- split tube

Charcoal- for tube based systems

Product Code

SERUTD-5065

Filter- split tube

Charcoal- for online systems and Kori-xr

Product Code

SERAAA-1600

Filter- split tube

Charcoal- for 4.5" (DAAMS) tube based systems

Product Code

SERAAA-5167

Filter- disk

Sintered PTFE- 5.1mm- 10 pack

Product Code

U-DISK1

Filter- disk

Sintered PTFE- 6.5mm- 10 pack

Product Code

U-DISK3

Filter- disk

Sintered PTFE- 3.2mm- 10 pack

Product Code

U-DISK4

Overview

Markes’ thermal desorbers offer quantitation of the widest possible concentration range, through flexible splitting of both inlet and outlet flows. Split flows can be collected onto a re-collection tube for storage or repeat analysis, but when not required, the split can also be collected onto a tube packed with charcoal for subsequent disposal.

Split filter tubes are available for three types of TD system:

- On-line systems use a glass industry-standard size tube

- Tube-based systems use a stainless steel industry-standard size tube

- 4½″ DAAMS tube-based systems use a stainless steel 4½″ long × 6 mm o.d. tube

Relevant part numbers:

SERAAA-1600 - SERAAA-5406 - SERUTD-5065 - U-DISK1 - U-DISK3 - U-DISK4