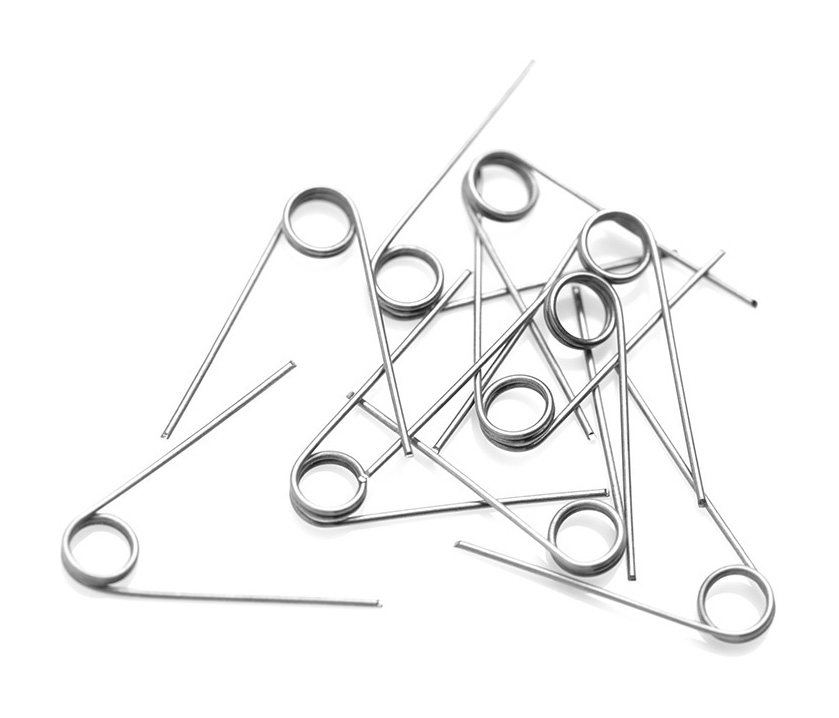

Springs

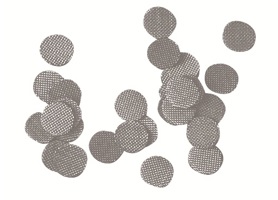

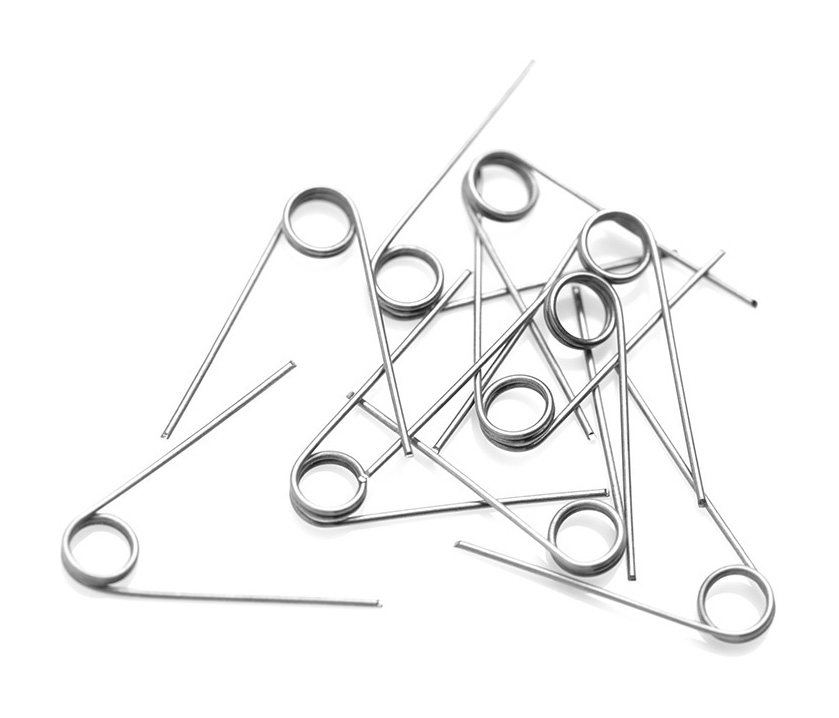

Gauze-retaining springs sit in the non-sampling end of metal tubes to maintain the correct positioning of the sorbent-retaining gauze. Torsion springs are used in glass tubes and focusing traps to hold a plug of quartz wool on the back of the final sorbent bed. In both cases they are used to secure the sorbent bed(s) in position.

- Prevents sorbent loss from tubes/traps during sampling, transport, storage and analysis

- Enables high flows to pass through tubes/traps

- Can be used to hold sample centrally in a tube for direct desorption

Product List

Showing 4/4 results

Spring- gauze retaining

10 pack

Product Code

C-SP010

Spring- gauze retaining

pack of 100

Product Code

C-SP100

Spring- torsion

For 4 mm sorbent tube- 10 pack

Product Code

C-GTSP10

Spring- torsion

For 2 mm focusing trap- 10 pack

Product Code

C-CTS10

Overview

Gauze-retaining springs have a curved design to maximise surface contact for enhanced grip. They sit securely in the non-sampling end of thermal desorption tubes, and only one is required per tube to hold the position of the sorbent-retaining gauze and (separately) the final sorbent bed. They are made of stainless steel, as they sit outside the flow path, and are suitable for use with 6 mm and ¼″ o.d. stainless steel and inert-coated tubes. Gauze-retaining springs can also be used to retain a sample, PTFE liner or bi-phasic sampling insert in an empty metal tube. The TubeMate tool is recommended to position gauze-retaining springs correctly.

Torsion springs sit securely in the wide-bore end of a focusing trap or the non-sampling end of a glass tube. The simple design minimises surface contact during insertion and removal to prevent internal surface clouding due to scratching, maintaining the transparency of the glass and ensuring the user can see its contents. Springs are used to hold the sorbent-retaining plug of quartz wool in position within the tube/trap (only one is required per restricted/fritted tube and in focusing traps).

When using unrestricted tubes for direct desorption, a plug of quartz wool and a torsion spring should be used on both the sampling and non-sampling end of the tube to prevent movement.

There is an option to double-up on springs when working with very high flows or prolonged sample times.

Note: There are two types of torsion springs to suit tubes with different inner diameters – 4 mm i.d. springs are recommended for use with industry-standard glass tubes and traps designed for TT24-7, whereas 2 mm i.d. springs are recommended for use with traps designed for UNITY-xr (and series 2), TD100 (all series) and Centri. Use of medical tweezers is recommended to position torsion springs correctly.

Part numbers:

C-CTS10 - C-GTSP10 - C-SP010 - C-SP100