How diffusion-locking technology cracked the problem of high-capacity thermal desorption automation

11 November 2022

DiffLok caps and SafeLok tubes

Josh Marshall reflects on a key technological advance in protecting sample integrity and its continued relevance for users of thermal desorption.

The thermal desorption automation conundrum

Today thermal desorption (TD) is recognised as the most powerful and versatile of all gas chromatography (GC) sample introduction technologies. It’s therefore sometimes easy to forget that it draws on several advances that we perhaps take for granted these days. One such example is diffusion-locking technology used in TD caps and tubes. Early attempts to automate tube-based thermal desorption involved use of caps that were removed and replaced during operation. However, they were found to be prone to significant loss of volatiles over time, compromising the integrity of valuable samples.

Today thermal desorption (TD) is recognised as the most powerful and versatile of all gas chromatography (GC) sample introduction technologies. It’s therefore sometimes easy to forget that it draws on several advances that we perhaps take for granted these days. One such example is diffusion-locking technology used in TD caps and tubes. Early attempts to automate tube-based thermal desorption involved use of caps that were removed and replaced during operation. However, they were found to be prone to significant loss of volatiles over time, compromising the integrity of valuable samples.

A promising approach

The team at Markes International started to explore a new approach, whereby tubes could be automatically desorbed without the need to uncap and recap them. If they could find a viable solution to this, it would protect the integrity of sampled and desorbed tubes and radically simplify the automated TD process thereby enabling the development of higher-capacity and more reliable autosamplers.

The challenge was to find a simple mechanism that would keep tubes sealed at ambient pressures while still allowing carrier gas to flow when pressure was applied. The approach they arrived at harnessed their knowledge of the diffusion process and their understanding that the diffusion of vapours into/out of an attached sorbent tube can be reduced almost to zero if the flow path is sufficiently narrow and long.

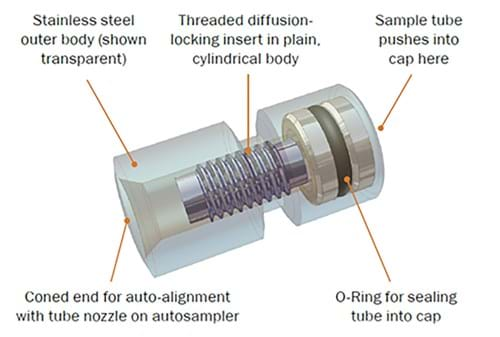

This enabled them to effectively eliminate diffusion into or out of conditioned tubes during automated analysis preventing both the loss of any sampled analytes and the ingress of contaminants from the lab air. The compact solution they came up with consists of a smooth stainless-steel cylindrical cap containing a stainless-steel threaded insert , creating a helical path of over 15cm long in a minimal space. And because this ‘diffusion-locking’ solution did not involve any kind of valve or other moving parts, it was inherently simple and robust.

Diffusion-locking technology

During the desorption process, when a tube is selected and sealed into the carrier gas flow path of the analytical system, pressure is applied, and carrier gas can flow through the caps and tube unimpeded. This greatly simplifies automation, because no uncapping or re-capping is required, reducing analyte losses and artefact ingress to negligible levels, even over extended periods.

This innovation was commercialised into Markes’ patented DiffLok™ capping technology, now used, throughout the Markes instrument range, by thousands of users worldwide.

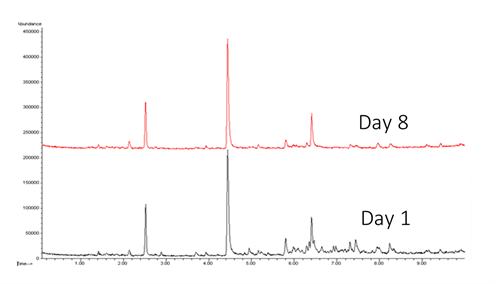

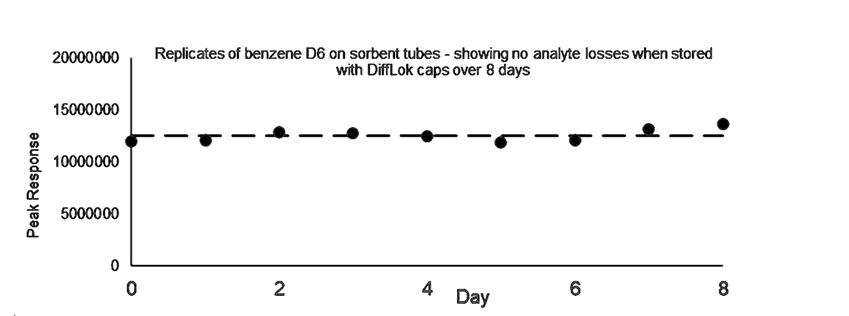

DiffLok caps have proved essential to protect sampled tubes from both ingress (see Figure 1) of laboratory air contaminants and the loss (see Figure 2) of retained volatiles. They also prevent contamination of desorbed/analysed tubes, which thus remain clean and ready for immediate re-use.

Figure 1: No artefact ingress over 8 days

Figure 2: No analyte loss over 8 days

Extending diffusion locking into SafeLok™ tubes

Markes engineers later found that the same kind of technology could be applied directly to the ends of sorbent tubes themselves. The resultant SafeLok tubes are specially machined with diffusion-locking threaded inserts pushed into each end. The beauty of the diffusion locking technology in this case is that it effectively eliminates any interference due to natural diffusion, thus allowing the use of pump flow rates as low as 1 mL/min for extended sampling periods. They are also great for researchers monitoring very low-level contaminants in background air – e.g. stratospheric and oceanic studies – because they minimize any risk of contamination during transportation and lab analysis.

Available in stainless steel or inert-coated stainless steel, SafeLok tubes are compatible with any TD instrument designed for use with industry standard tubes.

Schematic of SafeLok tube incorporating diffusion-locking inserts at both ends, shown here with two sorbent beds

Relevance for today

Diffusion locking technology remains as relevant as ever and is also integral to Markes Multi-gas (either helium, nitrogen or hydrogen) enabled range of instruments with capacity for up to 100 or 199 tubes in TD100-xr and ULTRA-Pro-xr respectively. These high-capacity autosamplers are a perfect complement to the high-speed and versatility of hydrogen carrier gas and other fast modern GC methods.

For questions about Markes diffusion-locking technology, please contact the team at sampletech@markes.com

![Markes TD Brochure Hero3 Corepurple[2]](/media/zmscvqds/markes-td-brochure-hero3-corepurple-2.jpg?cc=0.55128205128205132,0,0,0&width=350&height=260&v=1d660d04edbcca0)