Why ASTM D7892-2025 is a game-changer for hydrogen purity testing

30 July 2025

A new standard for trace-level monitoring in hydrogen fuels

As the global energy transition gathers pace, hydrogen is emerging as a key clean fuel – but only if its purity can be guaranteed. Fuel cell technologies such as proton exchange membrane fuel cells (PEMFCs) are highly sensitive to volatile organic impurities like chloromethane, benzene, and formaldehyde, which can degrade catalyst performance and shorten system lifespan, even at sub-ppb concentrations.

This is especially critical for fuel cell electric vehicles (FCEVs), backup power systems, and hydrogen-powered aerospace, where even trace contamination can compromise safety, reliability, or efficiency.

To address this, ASTM International released a revised version of ASTM D7892 on 7 July 2025. This standard – ASTM D7892-2025: Standard Test Method for Determination of Total Organic Halides, Total Non-Methane Hydrocarbons, and Formaldehyde in Hydrogen Fuel by GC–MS – establishes a modernised, harmonised approach for trace-level impurity analysis.

Why this update matters now

Hydrogen adoption is accelerating – but so too are regulatory expectations. National and international standards like ISO 14687, SAE J2719, and now the revised ASTM D7892-2025 method are tightening requirements for fuel quality, especially for mobility applications.

What sets ASTM D7892-2025 apart is its support for cryogen-free workflows, which simplifies lab operations while maintaining sensitivity and reproducibility. The method reflects growing demand for cleaner, safer, and more scalable monitoring solutions.

For full details on how to comply, visit our ASTM D7892-2025 method page.

Technical barriers to ultra-trace impurity detection

Monitoring volatile impurities at the sub-ppb level isn’t straightforward. Several technical hurdles must be overcome:

- Formaldehyde detection: Formaldehyde is both volatile and water-soluble, making it particularly vulnerable to humidity. Without effective water removal, detection can be inconsistent.

- Interferents: Co-elution of other trace compounds can obscure target analytes under complex chromatographic conditions.

- Cryogenic variability: Traditional cooling with liquid nitrogen or CO₂ introduces manual intervention, safety issues, and analytical variability.

These challenges have often limited broader adoption of trace-level impurity testing. The new standard addresses them head-on.

Enabling cleaner, more accessible workflows

ASTM D7892-2025 supports the use of cryogen-free technologies such as Peltier-based cooling for analyte focusing. This shift unlocks several practical benefits:

- Lower operational costs (no cryogen purchase or handling)

- Reduced system downtime and improved safety

- Simpler integration into labs without cryogenic infrastructure

By embracing cryogen-free workflows, the standard helps make high-sensitivity hydrogen testing more accessible to labs across diverse sectors and geographies.

How Markes supports hydrogen impurity testing

While ASTM D7892-2025 does not mandate specific instrumentation, it does describe a workflow that requires container-based sampling, preconcentration, and water abstraction – all of which are supported by Markes systems.

Our recommended configuration:

- UNITY–CIA Advantage-xr – A certified, cryogen-free thermal desorption system for gas bags and canisters. Offers multi-channel support and seamless integration with GC–MS. Learn more on our hydrogen fuel impurities page.

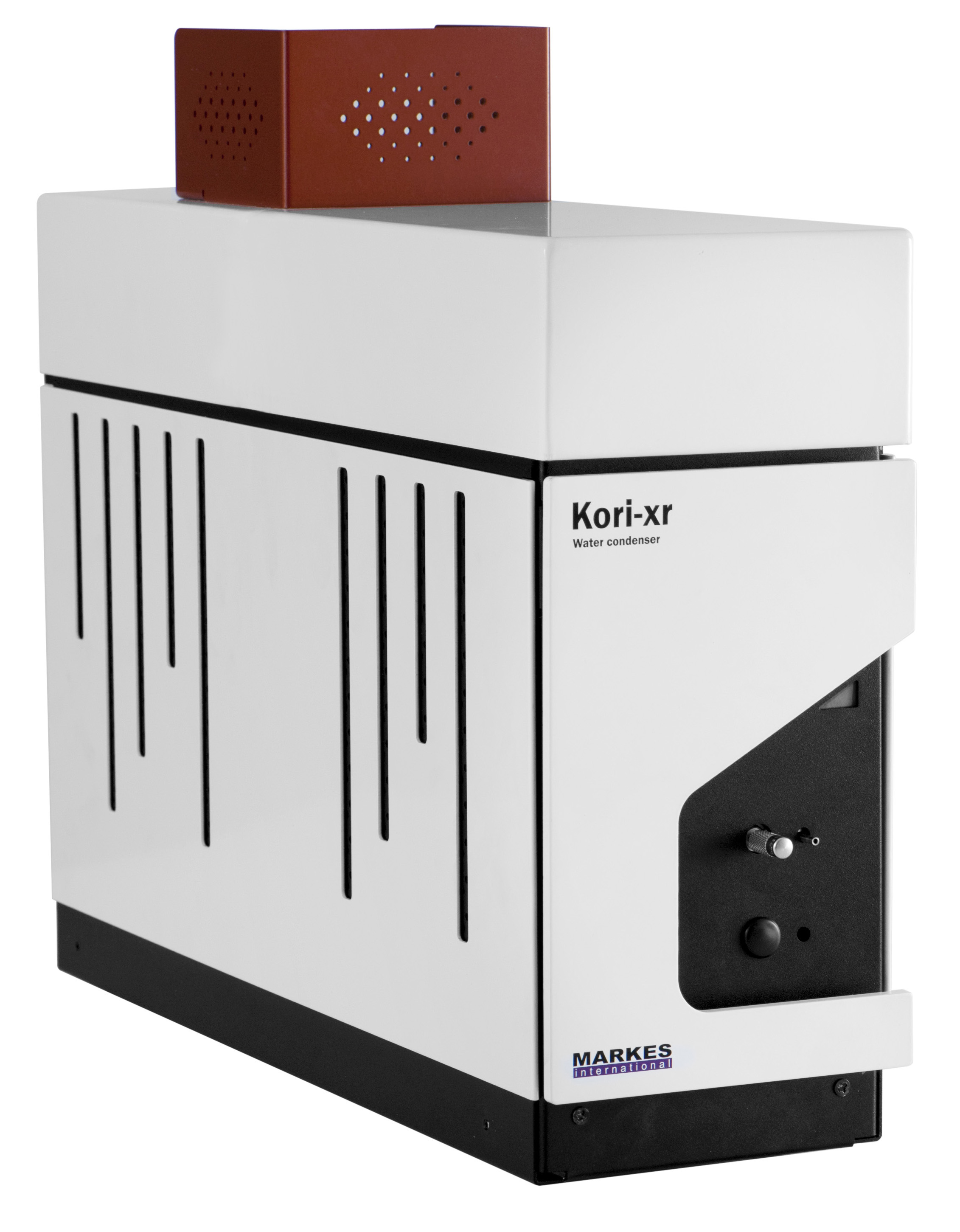

- Kori-xr – A Peltier-cooled water management module that selectively removes moisture, critical for accurate formaldehyde quantification.

- Gas sampling bags – Compatible with field protocols and validated for use with ASTM D7892-2025.

Together, these components provide a robust, compliant solution for labs adopting the revised method.

For more background on national regulatory requirements, view our poster: How to comply with national hydrogen standards.

Ready to modernise your hydrogen testing?

If you're looking to implement ASTM D7892-2025 or want to improve the sensitivity and sustainability of your hydrogen analysis, our team can help.