RFID tags for sorbent tubes (TubeTAG)

Markes’ patented TubeTAG technology is a unique RFID tagging and labelling system for thermal desorption tubes. TubeTAG allows automatic tracking of sample information from sampling through to analysis, and/or tube specific information (such as sorbent type or number of thermal cycles) to be associated with a tube for its lifetime.

- Sophisticated and fail-safe solution for recording tube history and tracking tubes in transit

- Can be written to/read online (on a Markes instrument), and offline using a TAGSCRIBE

- Relevant sample information is recorded in the sequence history when using TubeTAG on an automated Markes instrument

Product List

Showing 8/8 results

Starter kit

Essential TubeTAG

Product Code

C-TAGKT

TubeTAG

For stainless steel/inert-coated tubes- 10 pack

Product Code

C-TAG10

TubeTAG

For stainless steel/inert-coated tubes- pack of 100

Product Code

C-TAG100

TubeTAG

For glass tubes- 10 pack

Product Code

C-TAGG10

TubeTAG

For glass tubes- pack of 100

Product Code

C-TAGG100

TAGSCRIBE

For offline reading and writing of TubeTAG

Product Code

C-SCRIBE

TubeTAG Tool

For fixing/removal of TAGs from stainless steel/inert-coated tubes

Product Code

C-TAGTL

TubeTAG key

For fixing/removal of TAGs from glass tubes

Product Code

C-TAGKY

Overview

TubeTAG™ is a robust radio-frequency identification (RFID) tag that fits securely onto stainless steel or glass tubes. It allows for a more intelligent tube tracking approach (when compared with barcodes and serial numbers) whilst eliminating transcription errors, providing a chain of custody through field monitoring and lab analysis. The use of TubeTAG is recommended by key standard methods such as US EPA Method 325.

TubeTAG is compatible with Markes’ entire range of thermal desorption systems and can easily fit to your existing industry-standard tube stock.

With the use of a Markes automated thermal desorption system loaded with MIC (Markes Instrument Control) software and/or a TAGSCRIBE™, you can read and rapidly update tube and sample information such as sorbent packing, number of thermal cycles, pressure ratio, sample location and sample start/end times.

The design of TubeTAG is slightly different for stainless steel and glass tubes, but the principles and workflows are the same.

TubeTAGs are generally used in two ways when using a Markes automated TD system:

Sample-specific mode

The TubeTAG is attached to a conditioned and capped sorbent tube in the laboratory before being dispatched for sampling. The TubeTAG stays with the tube in the field, allowing sampling information to be logged. On return to the laboratory, the tube is analysed, and the sample information is recorded in the sequence history before the information is cleared and the tag is removed from the tube. The tag is then ready to be used with another conditioned and capped sorbent tube.

Tube-specific mode

The TubeTAG is associated with a specific sorbent tube for its whole lifetime. The TubeTAG holds basic tube information (such as sorbent packing and serial number), and allows logging of both tube-specific data obtained through analysis and its sampling history (such as number of thermal cycles, pressure ratio, tube status, sample location and sample start/end times).

Part numbers:

C-SCRIBE - C-TAG10 - C-TAG100 - C-TAGG10 - C-TAGG100 - C-TAGKT - C-TAGKY - C-TAGTL

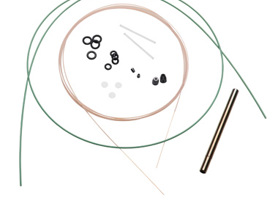

Starter kits list of contents

- 1 x C-SCRIBE, TAGSCRIBE

- 1 x C-TAG10, TubeTAG for stainless/inert tubes, pk 10

- 1 x C-TAGTL, TubeTAG tool

- 1 x C-TCFP10, Long-term storage caps (one TAG-ready, one standard), pk 10 pairs

- 1 x C-TAGLOK, TAGLok tool