Direct desorption/thermal extraction

Direct desorption is a variation on the principle of dynamic headspace that can be used to rapidly screen small quantities of solid or semi-solid materials. Small samples are placed directly into empty TD tubes or via tube liners. These are then heated in a stream of inert gas to sweep volatiles directly from the sample matrix onto the focusing trap of the thermal desorption instrument, for subsequent analysis by GC.

Direct desorption is typically applied to homogeneous waxes, powders or pastes. Analytes monitored are generally in the range C3 to C30. Applications of direct desorption include the odour profiling and quality control of a range of materials:

- Residual volatiles in ointments, packaging films, pharmaceuticals/drug powders and polymer beads.

- Emissions from consumer goods, such as paints, car trim components, moulded PVC and adhesives.

- Characteristic vapour profiles from foodstuffs and fragrant products, including soap powder and shampoo.

Overview

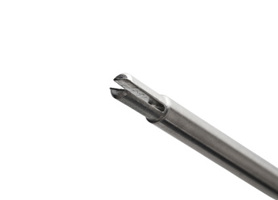

Glass tubes are normally used for direct desorption to make method development easier, as the physical state of the sample can be easily seen after each desorption. Two types of tubes can be used:

- Tubes without a restriction at either end can be used if the product is retained between two plugs of quartz wool, which can be held in place with small torsion springs.

- Tubes with a restriction at 30 mm from one end ensure that the sample is positioned correctly relative to the TD oven. A quartz wool plug and a torsion spring can be positioned at the non-sampling end to keep it in place.

Benefits of direct desorption

- Combines sample preparation, analyte extraction and sample introduction into an efficient and cost-effective operation for sampling of VOCs and SVOCs.

- Improves method stability by eliminating interferences such as non-volatiles, water and solvents prior to analysis.

Provides a ‘gas extraction’ or ‘dynamic headspace’ alternative to conventional solvent extraction, which eliminates solvent interferences and improves sensitivity.