Sorbent tube conditioning

Conditioning refers to the process of heating sorbent tubes under a flow of clean carrier gas to minimise artefacts and remove contamination. In any sampling campaign employing thermal desorption tubes, it is vital that the sorbent bed is free from contaminants before sampling commences. This avoids complications during analysis and minimises the potential for false-positive results.

Sample tubes are normally adequately cleaned by the analytical desorption process itself, but this may not be the case when tubes are freshly packed with sorbent or stored without being properly capped. Furthermore, heavy contamination can occur during sampling of atmospheres of unknown composition. Conditioning may also be required prior to trace-level monitoring. For these reasons tube conditioning plays an important role in building confidence in data. Freshly packed sorbent tubes conditioned and capped for immediate use mean quicker results.

Buy online

Overview

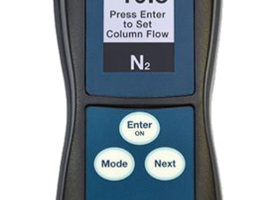

To improve lab productivity, stand-alone conditioning or dry-purging units such as the TC-20 can be used, offering benefits including:

- Freeing up the analytical instrument by conditioning multiple tubes off-line

- Cost savings by conditioning with nitrogen rather than helium

- Eliminating risk of contamination of the analytical instrument