How long do sorbent tubes for thermal desorption last?

21 March 2023

Knowing when to replace your sorbent-packed TD tube is a question we hear frequently from customers – and the short answer is that it depends! So in this blog post we discuss the factors that can lead to a reduced lifetime for a sorbent tube, how you can identify when to replace your tubes, and what to do when that happens.

Sorbent tubes can typically be re-used 100–400 times, making them environmentally friendly and providing a low cost per sample. Although there are some factors that can result in a lower lifetime, the good news is that it’s not difficult to anticipate when an individual tube will need to be replaced.

What are the factors that reduce sorbent tube lifetime?

Sorbents for TD tubes are rather like the phase on your GC column – after a certain number of heating and cooling cycles, the performance will decrease. By this, we typically mean that the tube loses the ability to retain the compounds of interest, and/or that the background starts to interfere with the analysis.

But how quickly a tube loses performance can be accelerated by three main factors:

- Dirty sampling environments: If the environment has high concentrations of particulate matter, oxidising agents or very high matrix, extra (or hotter) conditioning cycles may be needed to return the tube to a clean state, shortening the sorbent’s lifetime. Sometimes it’s not possible to mitigate against these sorts of conditions, but in situations where the matrix is known to be challenging, implementing filters or taking smaller volumes can help preserve the sorbent for as long as possible.

- High desorption temperatures: For obvious reasons, it’s difficult to avoid the high temperatures needed for efficient desorption of all the volatiles collected. But having said that, if TD tubes are conditioned and regularly desorbed close to the sorbent’s maximum temperature limits, the sorbent lifetime will fall more quickly. So you can make a difference by identifying the lowest possible desorption temperature by thorough method development. In fact, this often has additional benefits in the shape of better analytical results, and a reduced need for maintenance and replacement of consumable items.

- Mechanical ‘wear and tear’: Finally, some sorbents, mainly graphitised carbon blacks, can be ‘friable’ – meaning they’re susceptible to breaking up if the tube is handled roughly or dropped. So if you do drop a sorbent tube, we’d recommend assessing whether the sorbent might have been damaged in the process (an obvious sign is if the sorbent starts to leak from the tube).

How can you determine when a sorbent tube needs to be replaced?

If the performance of a tube starts to fall, then clearly you’d want to replace it. Fortunately, there are two ways to make this judgement that are better than simply relying on spotting when a tube is giving a poor result: sorbent background monitoring, and validating retention volumes.

Sorbent background monitoring

Monitoring of the sorbent background can be assessed in two ways:

- Comparing the concentration of target compounds in the sorbent tube blank against the method detection limits (MDLs). If compounds are present above the MDL in the blank after multiple reconditioning cycles, this can be an indication that the tube should be removed from circulation.

- Monitoring the total level of all compounds within the blank, usually semi-quantified using equivalent compounds. Once the background reaches a user-defined level, the tube can be removed from use.

Validating retention volumes

Validating compound retention volumes is simple to carry out, and can be achieved by breakthrough testing. We always advise testing target compounds and validating breakthrough volumes for the type of sorbent tube you’re using, and having done that, the ‘safe sampling volume’ is easily calculated by halving the breakthrough volume.

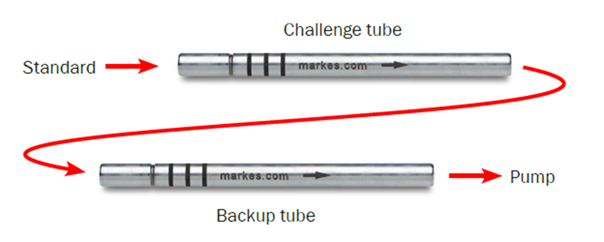

The image below shows how a breakthrough test should be carried out:

The sorbent tubes are first joined together by a union to allow analytes to transfer from the challenge tube to the backup tube. A standard containing the target analytes is then spiked onto the challenge tube and a pump connected to the backup tube, with the flow rate and sampling duration set to match the parameters required for sampling. The test is then repeated at the same flow rate but at 2–4 times the volume. In each case, both tubes are then analysed to see if any analytes have been purged from the challenge tube to the backup tube. If more than 5% of a compound is detected on the backup tube, then breakthrough from the challenge tube has occurred.

In the early stages of a new project, it is worth re-validating the breakthrough volume once the tubes have been through 50–100 thermal cycles. This can help you understand how long they can be used for before the performance drops below the level you need. With that information to hand, it’s then a straightforward matter to remove tubes from circulation after the defined number of thermal cycles.

A crucial task – keeping a tube log

It may seem an obvious point, but a key aspect of knowing when a tube needs to be replaced is keeping a log of the tubes, along with information about the sampling campaign and the number of times they’ve been thermally cycled. Every Markes tube comes with a barcode and serial number to help you do this, and tools like the tube barcode scanner and TubeTAG can help you automate the tube-logging process.

![Markes TD Brochure Hero3 Corepurple[2]](/media/zmscvqds/markes-td-brochure-hero3-corepurple-2.jpg?crop=0.55128205128205132,0,0,0&cropmode=percentage&width=350&height=260&rnd=132399686846500000)